Shop Routing

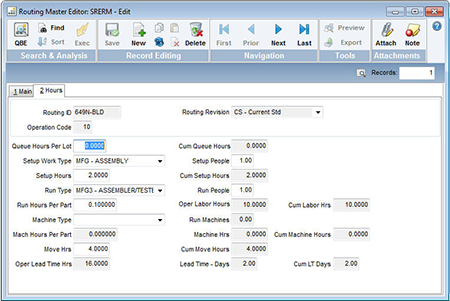

Detailed, accurate scheduling, costing and WIP tracking are achieved through the SHOP ROUTING system that provides routing master data, defining the sequence of operations required to manufacture a part.

Data maintained by each operation includes operation code, work center/vendor, queue hours, set-up hours, run hours, move hours, yield percentage and procedure descriptions. A vendor can be referenced if the work is performed at an outside manufacturer. Flexibility includes tooling control and alternate routings per product.

A utility is provided for calculating daily work center labor and machine loads for open operations on routing jobs, using setup and run hours.

Each operation’s load is based on the balance currently at the operation plus any expected quantity yet to be delivered from a prior operation. Positioned by Shop Day, the resultant load can be compared to capacity in graphical format on the Work Center Load report.

MODULE FEATURES

Work Centers

- Labor only

- Machine only

- Both labor and machine

- Outside processing vendor operation

Work Center Definitions

- Description of work center

- Department

- Browse by work center or department

- Location

- Machines

- Class code

- Number of hours per day

- Efficiency factor

- Shifts

- Operational hours per day

- Labor efficiency factor

- Productivity percentage

- Standard labor rate

- Standard labor burden

- Queue hours per work center

- Reporting by work center or department

Job Creation

- Create jobs from MRP Inquiry

Routing Maintenance

- Standard routings (master routing)

- Alternate routings

- Routing copy capabilities

- Routing hours roll-up

- Operation data

- Indirect and direct labor

- Outside processing

Operations Data

- Operation code

- Work center

- Yield percent

- Queue hours

- Setup hours

- Direct and indirect labor

- Operation lead time

- Run hours

- By labor and machine

- Move hours

- Lead time (Queue + Set-up + Greater of Labor/Machine Run + Move)

Routing Cost Variance Analysis

- Labor, material, outside processing, standards change, scrap

- Standard versus actual costs Report selection by part, job

Routing Costing

- Effective date control

- Operation added and cumulative costs:

- Labor

- Labor burden (factory overhead)

- Materials

- Outside processing burden (overhead)

- Work center control of:

- Standard labor rate

- Standard labor burden

- Option to include yield and scrap

Tooling Requirements

- Browse capability by tool part ID or alpha search name

- Tool part ID

- Tool description

- Storage location

- Cost

- Expected life

- Tool status

- Drawing ID, drawing revision and ECN

- Responsible engineer

- Buyer and vendor

- Substitute tool

- Routing where used

Reports and Inquiries

- Routing master

- Routing-part cross reference

- Operational tooling list

- Work center load

The Routing Master Editor displays the resources required to build a part at a specific operations step

Real-time Integration

- Inventory Control

- Purchasing

- Product Data Control

- Job Scheduling/Costing

- Materials Management (MRP)