Materials Management

MATERIALS MANAGEMENT is the first step in the execution of your plan. It defines the actions to be taken, and when to take them for buyers, planners, expediters and production schedulers.

The action messages of Expandable’s “bucketless” Material Requirements Planning (MRP) reporting are your company’s time-phased call to action.

Material requirements are generated based on a production schedule from the Master Production Schedule (MPS) or may be manually created.

MODULE FEATURES

Production Plan Maintenance

- Part demand by required dates

- Customer and user reference information

- Optionally created by Master

- Schedule Utility

- Load Sales Order demand directly into MRP Part Plan

Material Requirements Generation

- Include and exclude options:

- Select on release date

- Collect stock, open order status

- Analysis of safety stock

- Explode assemblies only

- Calculate component requirements

- Negative inventory

- Safety stock

- Expense items

- Shortages from closed jobs

- Purchase order requisitions, quotation, blankets

- On-hold purchase orders and jobs

- Lead time for phantoms

- Use part lot size or exact quantity

- Update part forecast in the Part Master File

- Select on part plan source

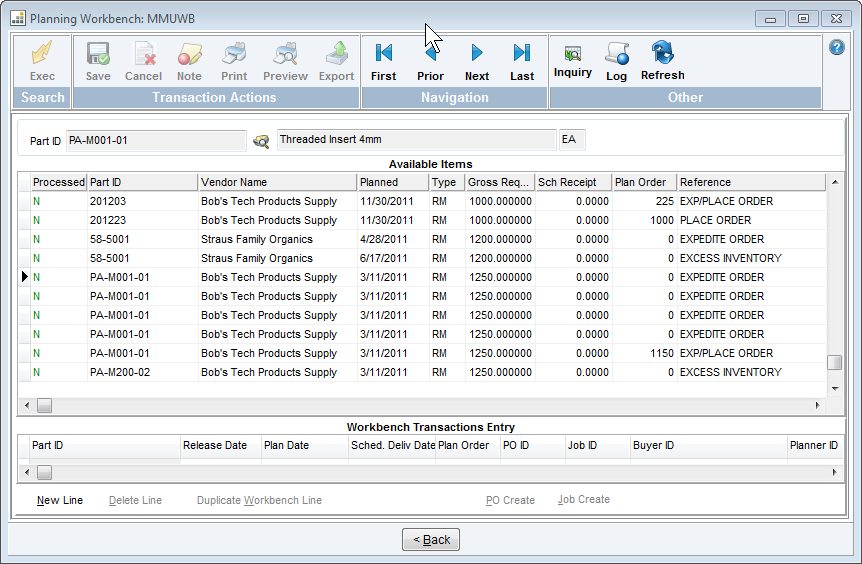

Planning Workbench

- Place jobs and purchase orders directly from MRP run

Material Requirements Reporting

- Top level pegging

- Bucketless calculation with summarized or detailed reports

- Selection by:

- Buyer

- Vendor

- Part

- Planner

- Date range

- Action message(s)

- Detail shows:

- Gross requirements

- Open orders

- Projected availability

- Planned orders

- Recommended release date

- Pegging data

- Parts user fields

- Action analysis:

- Recommended orders

- Recommended order re-scheduling

- Order past due

- No requirements

- Optional vendor info

Inquiries

- Material Requirements

- Option to create PO line or job from inquiry

- Pegging

- Part plan

Manufacturing Calendar Maintenance

- Generation by year

- Work days vs. non-work days

- Plant shut-down date range

The Planning Workbench simplifies the materials planning process

Multi-run Planning

- By plant

- Compare MRP runs

- Centralize purchasing

Real-time Integration

- Inventory Control

- Lot Tracking

- Purchasing

- Product Data Control

- Job Scheduling/Costing

- Master Scheduling