Quality Part Parameters

The optional QUALITY PART PARAMETERS (QP) module defines specification parameters (Min/Max/Ave) for parts, with the ability to define measurement instructions for common or like parameters. Users gain the ability to electronically capture multiple measurements against a product’s defined parameters with general in or out of min/max specification results and tolerances as compared to average typical specification.

The Quality Part Parameters module provides an engineering and/or production quality assurance organization electronic capture with the capability to pre-define a product’s specifications and instructions for measurement and then collect measured inspection data, process control measurements, process audit information, final inspection data, returned product evaluation and other critical product validation information.

MODULE FEATURES

The Parameter Measurement Instruction Editor (QPEMI) allows the user to define instructions for taking accurate measurements of specified product parameters.

Instructions can be classified by type/subtype, measurement device, effective date and end date.

Detailed instructions for taking measurements are directly linked to specifications for inspectors, testers and quality control personnel to reference as measurements are taken over the course of a product’s life cycle.

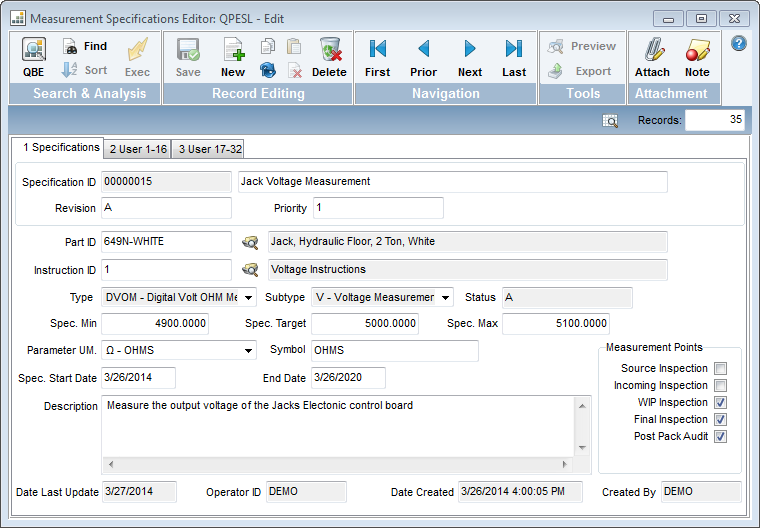

The Part Parameter Specification and Link Editor (QPESL) allows the specification of parameters linked to a PART ID and also link to a Measurement Instruction for the user making the measurement to reference.

Users can specify any number of parameters for an individual Part ID in the Part Master table and define link specification parameters (Min/Max/Ave) with units of measure and parameter symbol for parts, including the ability to link pre-defined measurement instructions common to the parameter.

Parameters can be defined for any or all of the following quality areas of inspection as required:

- Source Inspection

- Incoming Inspection

- WIP Inspection

- Final Inspection

- Post-Pack Audit Inspection

The Part Measurement Capture Editor (QPEMC) provides the means to capture physical measurements of a product at any stage and as many times as required in a product’s lifecycle to track the performance history of the product as compared to its pre-defined parameter specifications.

A grid entry user interface provides an easy-to-use method to log measured values and automatically calculate tolerance performance against typical and Min/Max ranges against the part’s specification for each measurement.

Grid entry values are automatically populated based on the user’s initial set up of the measurement, pulling those specifications that are applicable for the radio button selection of stage for the given measurement(s) to be taken: Source Inspection, Incoming Inspection, WIP Inspection, Final Inspection or Post-Pack Audit Inspection.

Data capture allows for three standard measurements per parameter with performance calculations along with three general observation fields.

All Part Parameter editors (QPEMI, QPESL and QPEMC) allow for ample variety of user-defined fields, date fields and flags providing additional flexibility in specification, instructions, measurement data collection and reporting metrics.

The Measurement Specifications Editor

User fields can be configured to support free text entry or locked to a pre-defined dictionary pull down menu selection to insure consistency of data entry for reporting purposes and performance data analysis or as required indicating additional product stage measurements.